OTHER METAL ORE

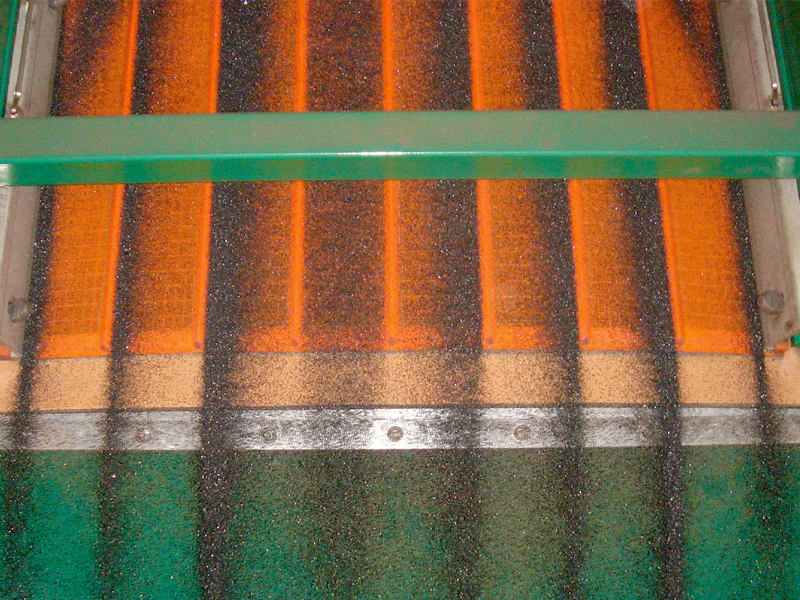

Other metals such as lead, zinc, platinum, chrome etc. are being fine screened through Derrick products worldwide. Whether it be Stack Sizer® or HI-G® Dewatering Screen or dry screen, with the combination of high frequency and unmatched high open area poly urethane screen panels, world class Derrick equipment can deliver outstanding outputs in mineral processing plants.

One platinum producer in Africa doubled chrome recovery with significant improvement in PGM recovery, reduced consumption of flotation reagents by replacing inefficient traditional classification equipment with Stack Sizer screening machines. The payback time was as low as seven months.

Let Us Find The Right Product For Your Application.

EXCLUSIVE BENEFITS

- Extremely low cost per ton of milled ore in closed grinding circuit

- Highly efficient classification compared to other traditional classifiers results in to improved product grade and recovery

- Low water and power consumption

- Low reagent consumption in downstream unit operations because of reduced amount of ultra- fines being generated

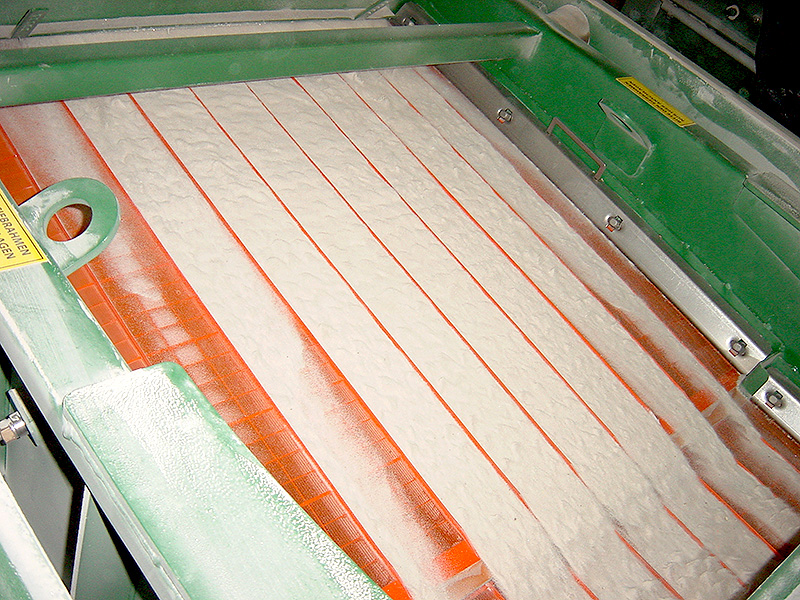

- Non-blinding, unmatched high open area, long lasting patented urethane screen surfaces

- >99% vibration isolation

- Self- lubricated vibrators

- Negligible dynamic load