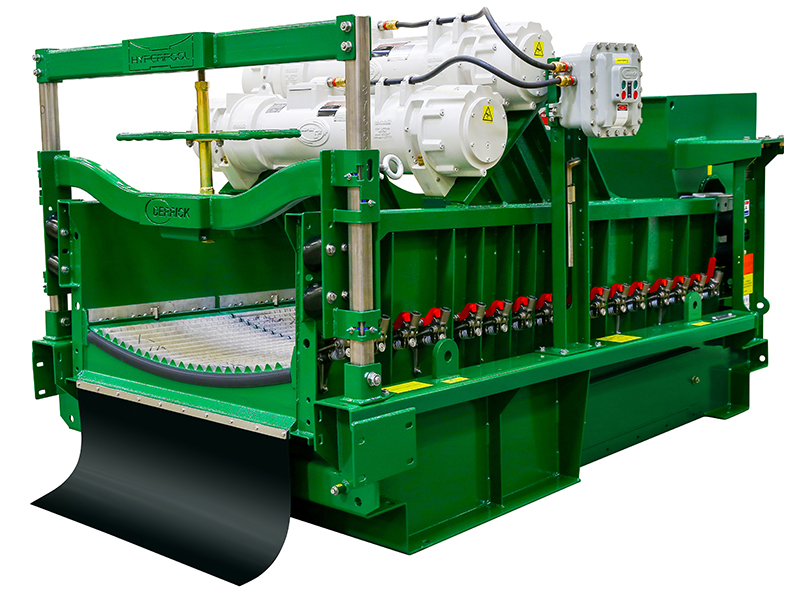

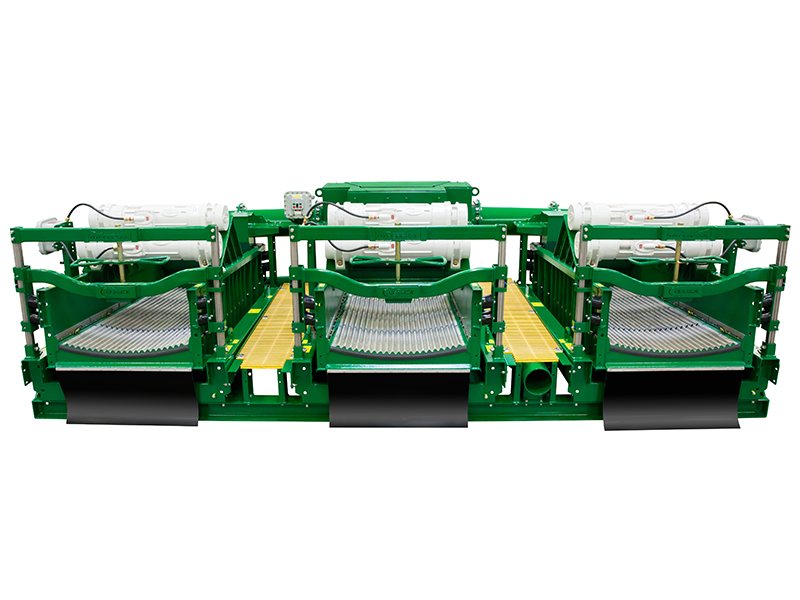

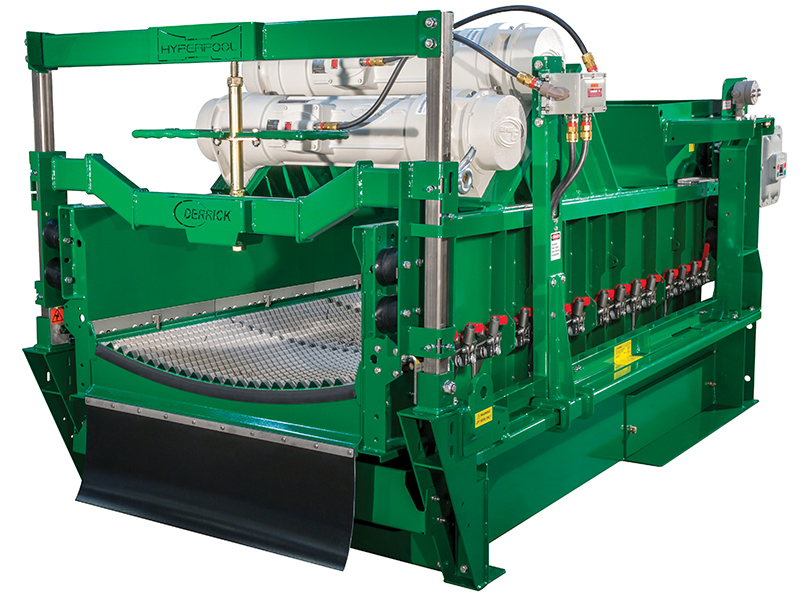

HYPERPOOL®

Backed by over 46 years of cost-effective solutions plus award-winning service, the Derrick Hyperpool® shaker is the latest in a long line of products designed expressly to exceed the demanding needs of today’s oilfield drilling operations.

With its compact footprint, industry-leading processing capacity, solids bypass prevention, and low maintenance cost, the Hyperpool is well suited for all drilling applications where drilling performance and rig modularity are required. The Hyperpool is designed to bring maximum value to the customer.

- Health, Safety, & Environment (HSE)

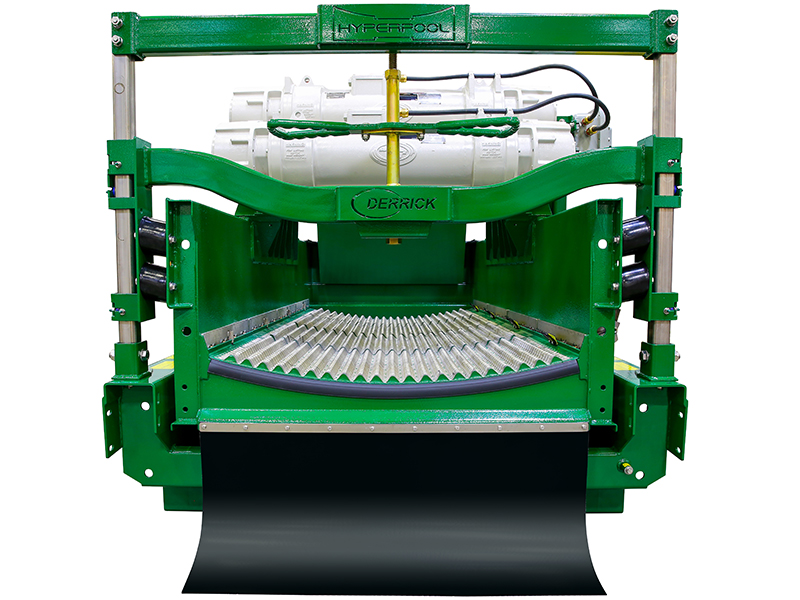

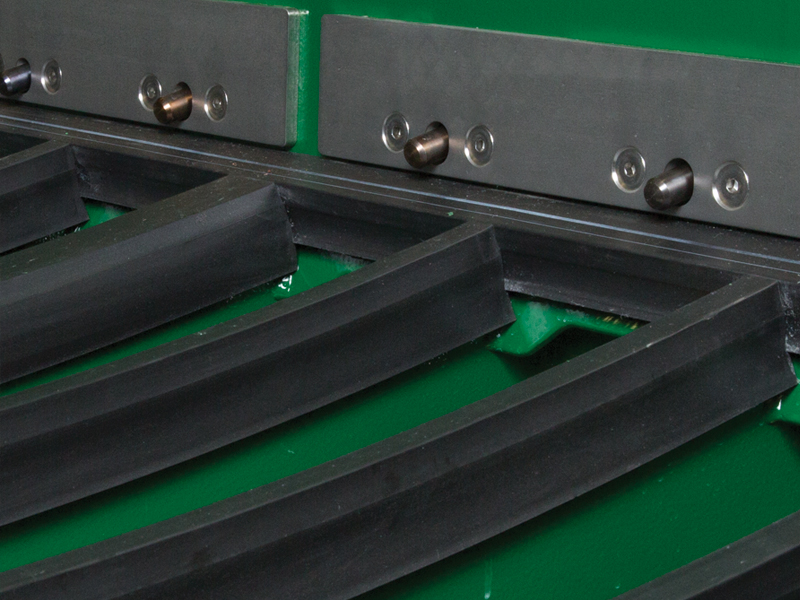

- Concave Screen Bed

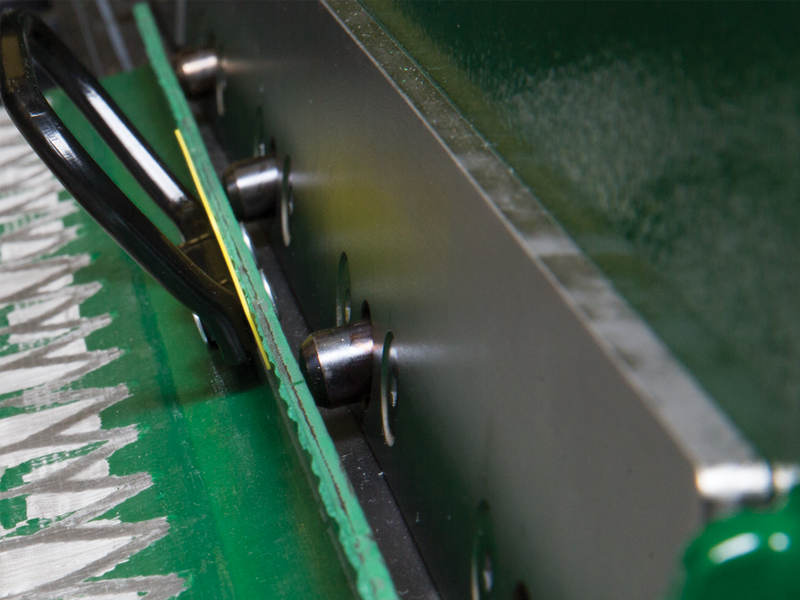

- Screen Compression System

- Pyramid® Screen Technology

- Super G® Integrated Vibratory Motors

- Single Point Screen Angle Adjustment

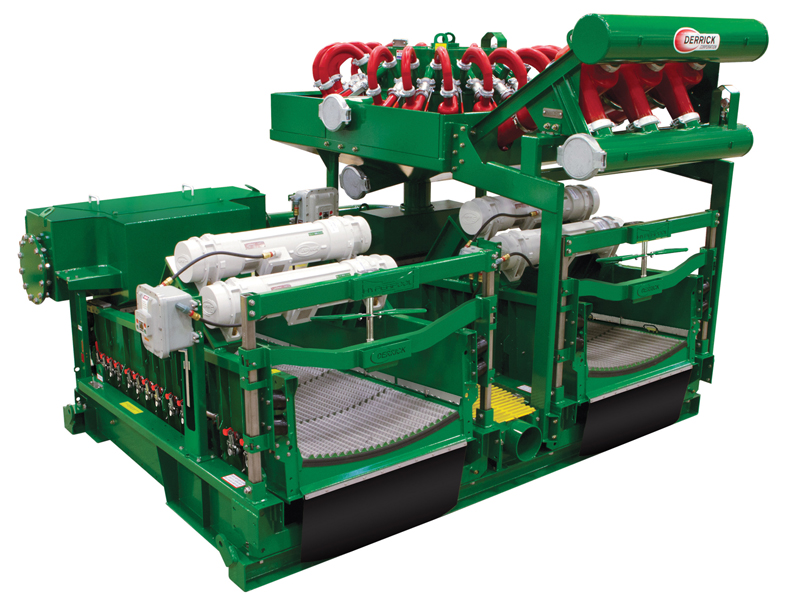

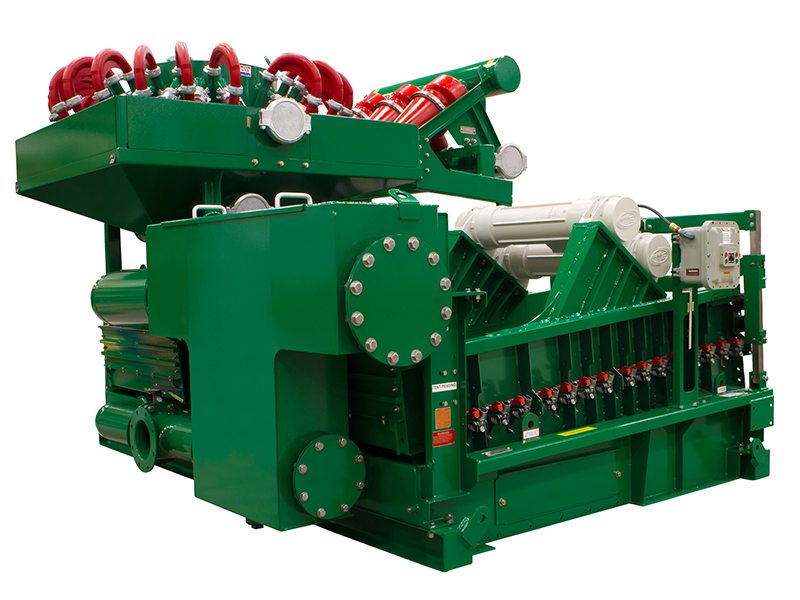

- Mud Cleaner

FEATURES & BENEFITS

- Easy screen inspection, removal, and installation

- Low sound production (74 +/- 4 dBA)

- Optional vapor extraction covers protect operating personnel and surrounding equipment from vapors emitted during the screening process (dependent on customer provided HVAC exhaust system)

- Optional self-locking splash covers provide clean operating environment

- Light-weight screen panels make for easy installation

- Eliminates bypass of solids under screen panels

- Fluid centering technology increases capacity up to 35% over competitive equipment

- Increased efficiency in a smaller footprint

- Compression fit bed material requires no hardware

- Less than 45-seconds per screen panel change

- Fast, secure panel retention

- Single-side operation, available in either left or right side

- Pyramid and Pyramid Plus™ screens offer up to 45% more API RP 13C non-blanked screen area over conventional shakers delivering greater efficiency

- Compliant with industry-standard API RP 13C (ISO 13501)

- Zero maintenance

- Powerful, quiet, dual vibratory motors apply high G performance

- Two options – Super G or Super G2®

- Standard Super G has greased-for-life bearings (Two-year warranty)

- Optional Super G2 has continuous recirculating internal oil lubrication system (Three-year warranty)

- Adjustable screen angle while drilling from +2° to +8° for optimum capacity, screen life, and efficiency

- Manual single point system allows one man operation and optimization while drilling

- Up to twenty 4” hydrocyclones

- Up to three 10” hydrocyclones

- Optional individual shutoff valve for each 4″ hydrocyclone

RELATED DOCUMENTS

Hyperpool Series

Fill out the form below to Download Brochure:

Hyperpool Conversion Kit

Fill out the form below to Download Brochure:

Field Report 143 – Hyperpool Shakers save major operator $261,384 in four well study in South Texas

Fill out the form below to Download Field Report:

Field Report 144 – Derrick Hyperpool greatly enhances solids removal with ability to run finer screen sizes up to API 230

Fill out the form below to Download Field Report:

Field Report 153 – Derrick saves Eagle Ford operator over $500,000 annually

Fill out the form below to Download Field Report:

Field Report 154 – Hyperpool Conversion Kit outperforms BRANDT KING COBRA HYBRID

Fill out the form below to Download Field Report:

Field Report 159 – Derrick® Hyperpool® reduces fluids costs by 38%

Fill out the form below to Download Field Report:

Field Report 164 – Derrick Hyperpool® Shale Shakers Reduce Drilling Costs in the Eagle Ford

Fill out the form below to Download Field Report:

Field Report 169 – Three Derrick® Hyperpools® Outperform Four Competitor Shakers in the Midland Basin

Fill out the form below to Download Field Report:

Case Study 100 – Derrick® Hyperpool® provides E&P operator in Sindh Pakistan with mud cost savings

Fill out the form below to Download Case Study:

Case Study 101 – DSI’s primary solids control optimization system saves major E&P operator over $205,000 USD per 17-1/2” hole section in Pakistan

Fill out the form below to Download Case Study:

Case Study 102 – Derrick® Hyperpool® saves major E&P operator over $128,000 USD per well in Pakistan

Fill out the form below to Download Case Study: