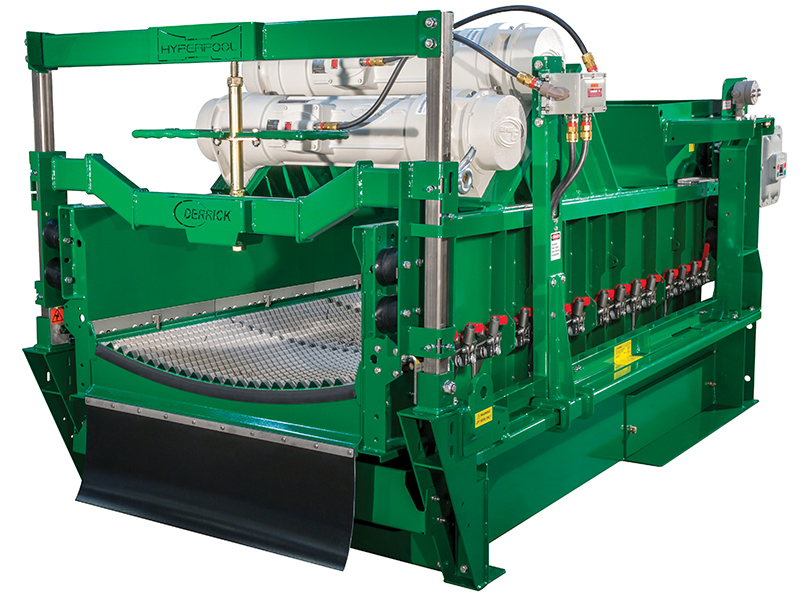

HYPERPOOL® KITS

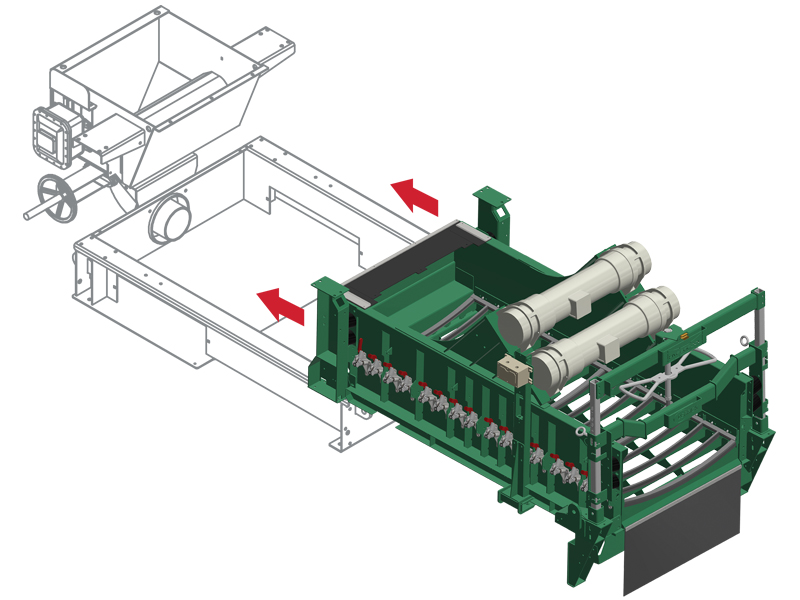

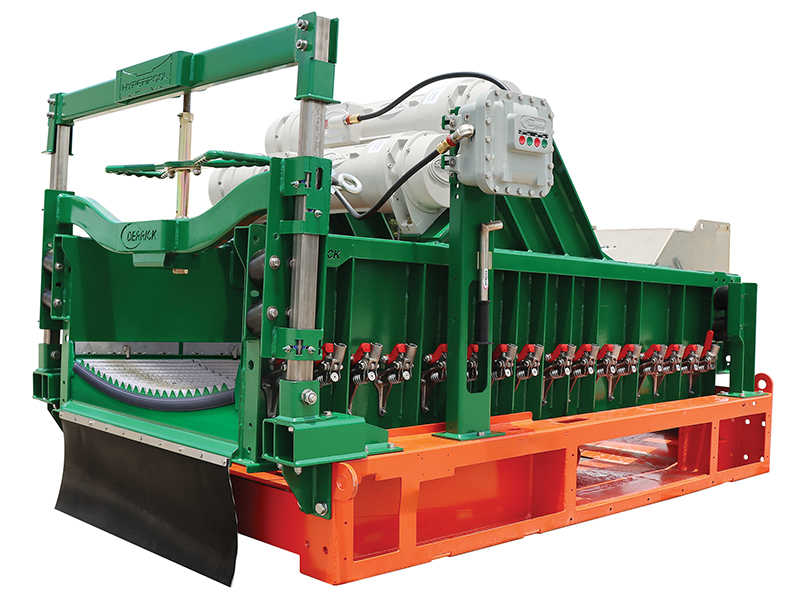

Derrick now offers the Hyperpool® Upgrade Kit designed to fit the Flo-Line Cleaner™ 503 and Flo-Line Cleaner 2000, as well as the Hyperpool Conversion Kit designed to fit the BRANDT KING COBRA, KING COBRA VENOM (K-Series), and M-I SWACO MONGOOSE series shakers (M-Series). The advanced design allows for easy installation without the need for welding, cutting, or changing the flow line and manifold.

The Hyperpool Kit features all the benefits of Derrick’s proven research and development technology found in the standard Hyperpool, such as simple screen changes, fluid centering technology, manual screen angle adjustment, and Pyramid® (PMD®) screen technology.

- Health, Safety, & Environment (HSE)

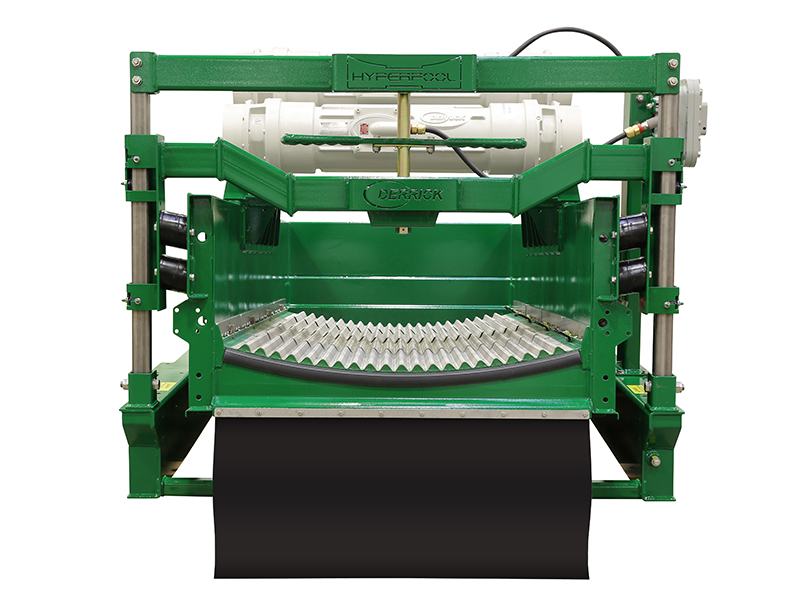

- Concave Screen Bed

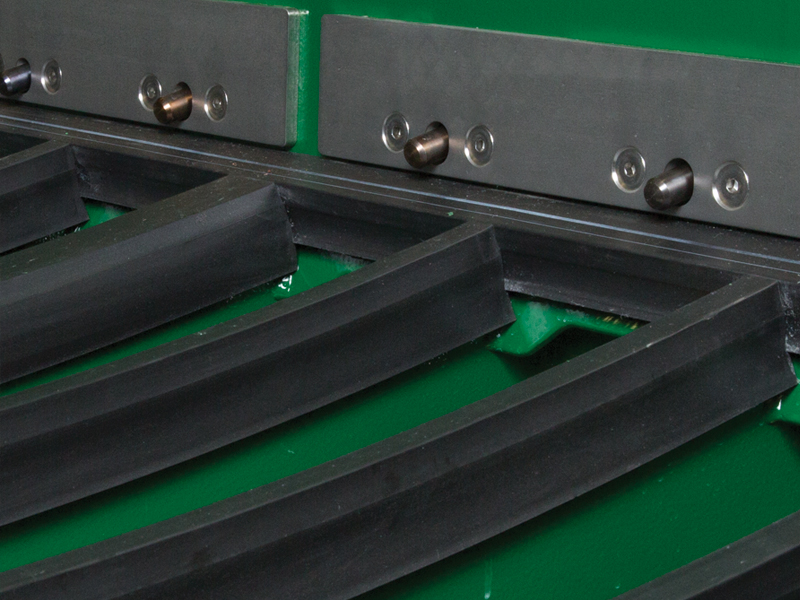

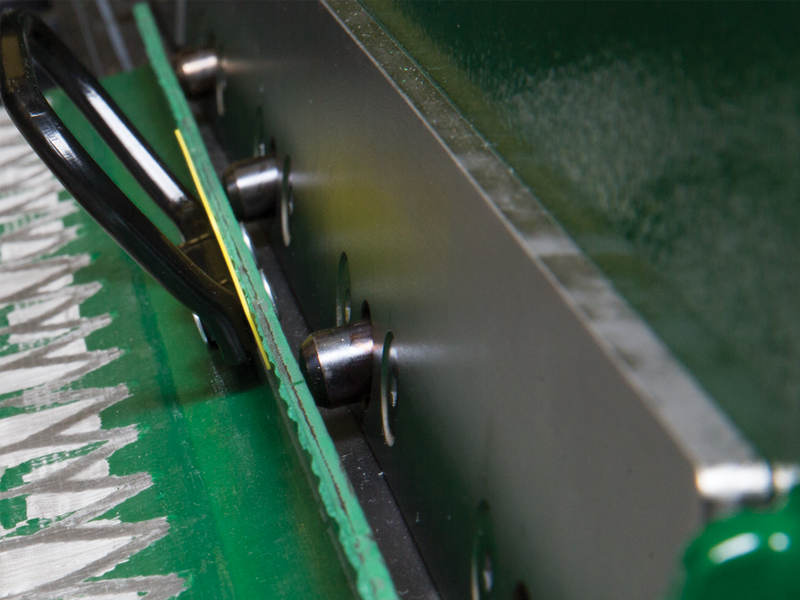

- Screen Compression System

- Pyramid® Screen Technology

- Super G® Integrated Vibratory Motors

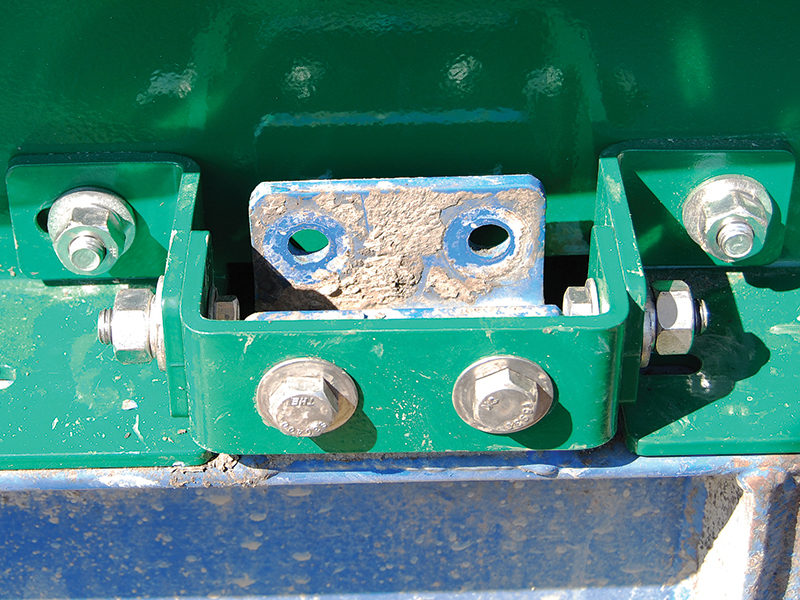

- Single Point Screen Angle Adjustment

BRANDT, KING COBRA, and VENOM are trademarks and/or registered trademarks of National Oilwell Varco.

BENEFITS

Optimize Drilling Process

- Higher rate of penetration

- Reduced non productive time and hole problems

- Reduced fluid loss

- Reduced waste volume

- Less wear on pumps and downhole tools

Maximize Your Shaker’s Potential with the Hyperpool Conversion Kit

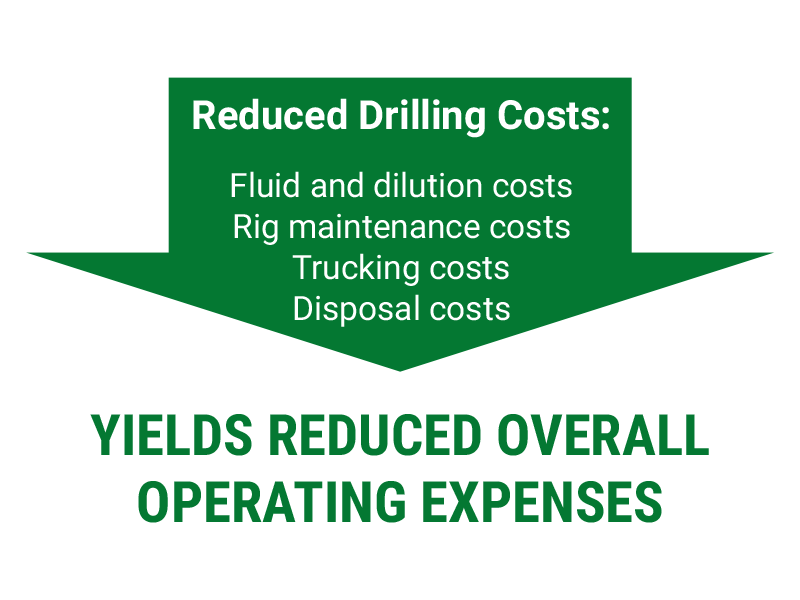

Fluid centering technology maximizes fluid throughput by causing fluid to pool in the center of the concave screen bed for maximum screening effect. Fluid centering technology, in conjunction with Pyramid and Pyramid Plus screen technology, enable the Hyperpool Conversion kit to process more wellborn returns than OEM shakers within the same footprint. Thus, the Hyperpool can screen finer, substantially increasing solids removal while still minimizing mud lost to cuttings. Maximizing solids removal at the flow line shakers is critical to maximizing drilling efficiency and minimizing total drilling costs, and lowering waste management costs to ease environmental concerns.

M-SERIES

INCREASED SOLIDS REMOVAL

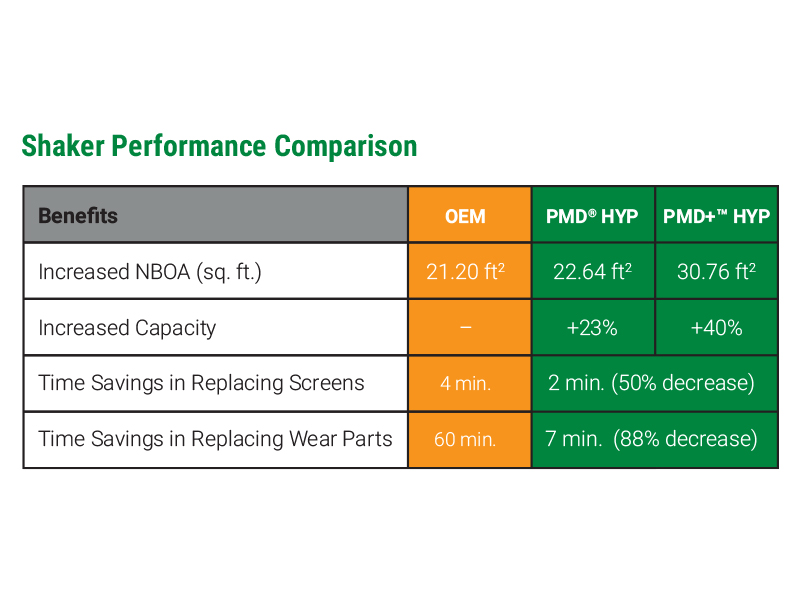

The Hyperpool Conversion Kit M-Series processes up to 40% more wellborn returns than competitive equipment within the same footprint.

INSTALLATION FOR 3 UNITS: UNDER 8 HOURS

K-SERIES

INCREASED SOLIDS REMOVAL

The Hyperpool K-Series shaker offers up to 35% increased capacity over competitive equipment within the same footprint.

INSTALLATION FOR 3 UNITS: UNDER 8 HOURS

FEATURES

- Easy screen inspection, removal, and installation

- Low sound production (74 +/- 4 dBA)

- Optional vapor extraction covers protect operating personnel and surrounding equipment from vapors emitted during the screening process (dependent on customer provided HVAC exhaust system)

- Optional self-locking splash covers provide clean operating environment

- Light-weight screen panels make for easy installation

- Eliminates bypass of solids under screen panels

- Fluid centering technology increases capacity up to 35% over competitive equipment

- Increased efficiency

- Compression fit bed material requires no hardware

- Less than 45-seconds per screen panel change

- Fast, secure panel retention

- Single-side operation, available in either left or right side

- Pyramid and Pyramid Plus™ screens offer up to 45% more API RP 13C non-blanked screen area over conventional shakers delivering greater efficiency

- Compliant with industry-standard API RP 13C (ISO 13501)

- Zero maintenance

- Powerful, quiet, dual vibratory motors apply high G performance

- Two options – Super G or Super G2®

- Standard Super G has greased-for-life bearings (Two-year warranty)

- Optional Super G2 has continuous recirculating internal oil lubrication system (Three-year warranty)

- Adjustable screen angle while drilling from +2° to +8° for optimum capacity, screen life, and efficiency

- Manual single point system allows one man operation and optimization while drilling

RELATED DOCUMENTS

Hyperpool Upgrade Kit

Fill out the form below to Download Brochure:

Hyperpool Conversion Kit K-Series

Fill out the form below to Download Brochure:

Hyperpool Conversion Kit M-Series

Fill out the form below to Download Brochure:

Reduce Overall Operating Expenses with Derrick Hyperpool Technology

Fill out the form below to Download Flyer:

Field Report 143 – Hyperpool Shakers save major operator $261,384 in four well study in South Texas

Fill out the form below to Download Field Report:

Field Report 153 – Derrick saves Eagle Ford operator over $500,000 annually

Fill out the form below to Download Field Report:

Field Report 154 – Hyperpool Conversion Kit outperforms BRANDT KING COBRA HYBRID

Fill out the form below to Download Field Report:

Field Report 157 – Derrick® Hyperpool® Conversion Kit reduces fluids and disposal costs by 24%

Fill out the form below to Download Field Report:

Field Report 165 – South Texas operator reduces dilution by 35% and decreases days on well by switching to the Hyperpool® Conversion Kit

Fill out the form below to Download Field Report:

Field Report 167 – Five cost saving results total $350,000 CAD from upgrade to Hyperpool® Conversion Kit shakers

Fill out the form below to Download Field Report:

Field Report 171 – Haynesville Operator Projects Annual Dilution Savings of $1.48M per Rig with Derrick® Hyperpool® Technology

Fill out the form below to Download Field Report: